Started from 2002, the company has become the world R&D and manufacturing base for tire mold, with products related to all types of molds, including TBR, PCR, OTR, earthmover tyre molds, new types of molds, and mold repair and remanufacturing services. It has an international market share of over 30% and has established stable cooperative relationships with 66 of the world's Top 75 tire companies.

Himile has become an influential high-end mechanical parts manufacturing base since its establishment in 2006, and it can provide one-stop services from design, casting, welding, and mechanical processing. The products include gas turbines, compressors, wind power gearbox, large wind power machinery, die-casting machinery, engineering machinery, and other fields. We have high-end customers such as GE, Siemens, Mitsubishi, Flender, ZF, NGC, and Dongfang Turbine.

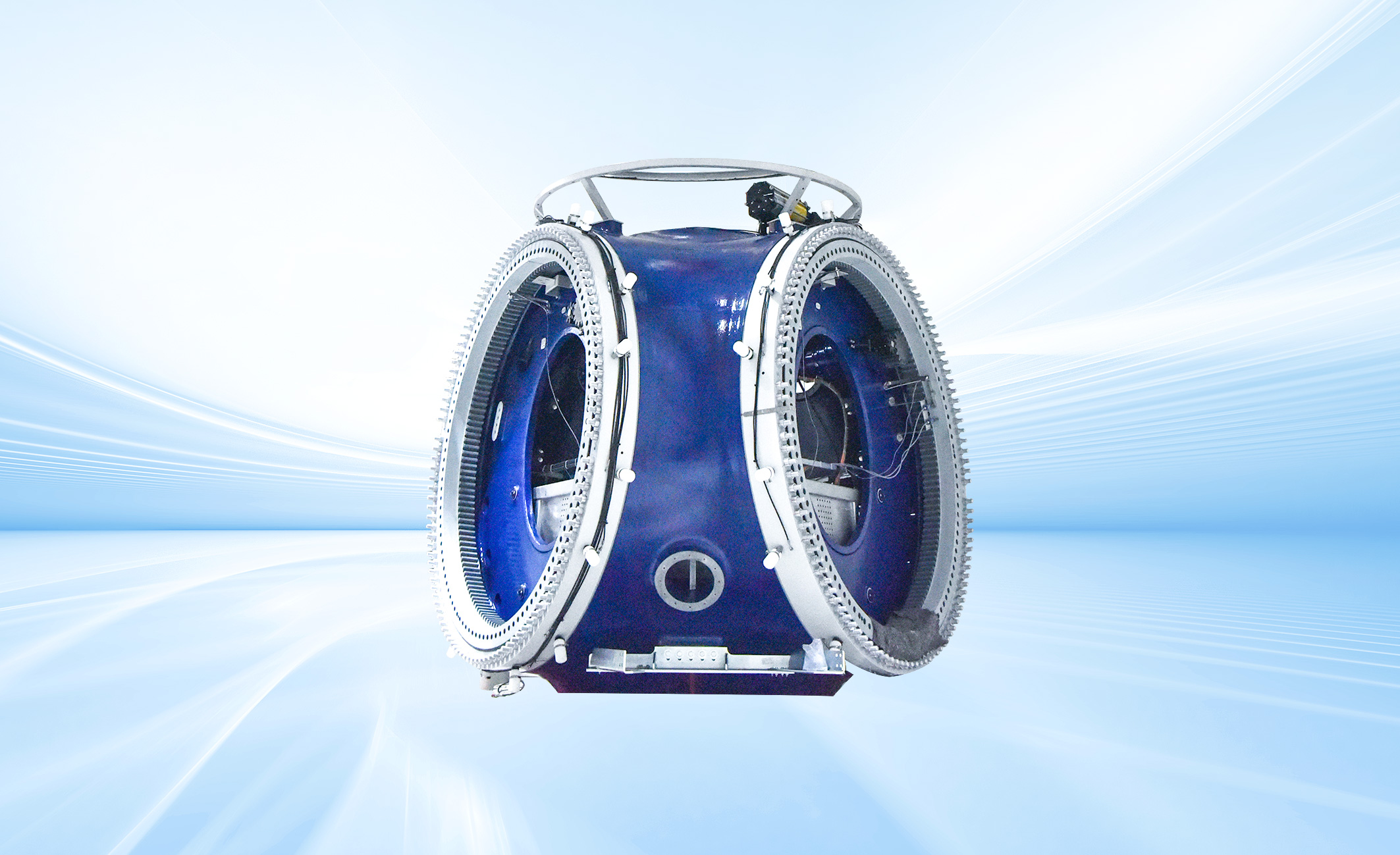

Himile has been committed to the research and development of machine tools and equipment when the company was established, focusing on providing CNC equipment and overall solutions for the equipment manufacturing industry. It has built an advanced CNC machining and production system, focusing on the development of three major directions: mid-to-high-end machine tools, key functional components, and rubber machinery. The products have been widely used in fields such as molds, medical care, automobiles, and 3C.

Founded in 2008, we have established stable cooperation with many world-class companies such as Baker Hughes, Schlumberger, MODEC and SBM, covering many files like subsea drilling and mining equipment, vessels, heat exchangers, skids, modules. We have two large production bases at Gaomi and Rizhao in Shandong province, and have newly established factories at Rushan in Shandong province and Chengmai in Hainan province to make up for the transportation shortcomings of oversized products weighing more than one thousand tons and deepen strategic cooperation with top customers in the world.

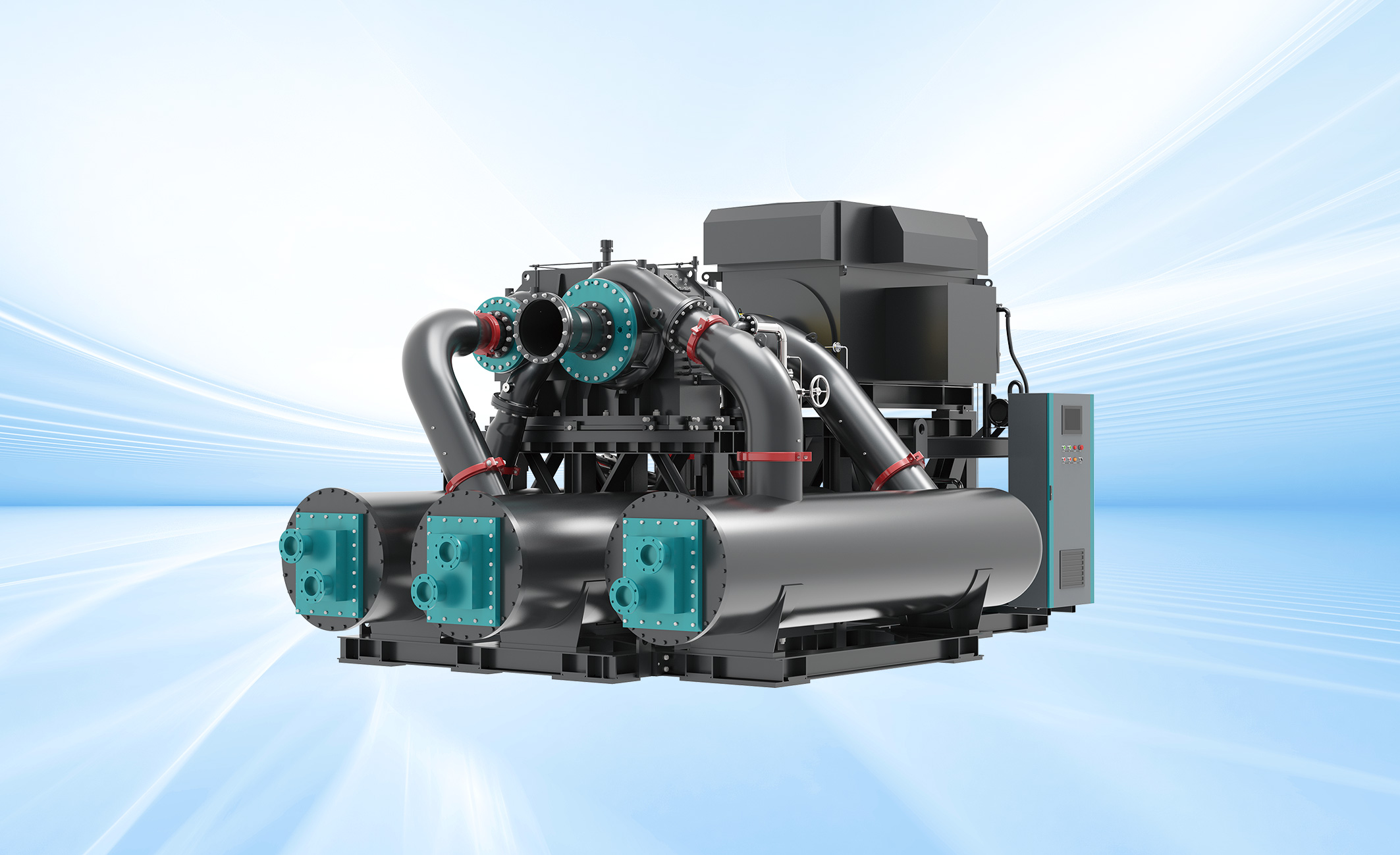

We have established R&D centers in Gaomi, Xi'an in China, and another R&D center in the United States, with a professional R&D team that can provide the research and development, design, production, installation, commissioning, services, and technical consulting services for compressors. At present, reliable and stable products such as centrifugal compressors, reciprocating compressors, and diaphragm compressors have been successfully developed. The centrifugal compressor has achieved full coverage of 40-2000Nm3/min models and can provide personalized customization according to customer requirements. It has been selected as one of Shandong's innovative industrial product catalogs and well-known brands in 2021. The 216kW-5580kW CH series model of high-speed reciprocating compressor has been developed and selected as a key research and development plan and high-quality brand in Shandong Province. The diaphragm compressor model has a power range of 3-185kW, a maximum flow rate of 3000Nm3/h, and a pressure of up to 100MPa. It is widely used in hydrogen energy, gas industry, fine chemicals, pharmaceuticals, pesticides and other fields.

The products serve for different industries, such as petrochemical industry, equipment manufacturing, construction machinery, ocean engineering, electric power, wind power, vehicle hub, etc. The main product is ultra-low VOC emission of water-based and high solid solvent high-end industrial anticorrosive coatings, meeting the latest national environmental protection requirements. We provide customers with integrated package solutions for coating system from supporting design, product supply, painting technique guidance to painting process control. We are committed to provide customers with high-quality, long-term products and services.

The under-construction Chemical Technology Research Institute covers business related to the entire industrial chain of chemical engineering, natural gas, and hydrogen energy. We have fluid laboratories, chemical laboratories, and thermal laboratories, which integrates optimization design of process system, industrial product customization, and on-site technical services. The company has independently developed more than ten types of continuous reactors, including micro-channel reactors, dynamic tube reactors, and MIC reactors, and has made personalized modifications based on the process characteristics of our customers. Aiming to achieve the integration of experiments, process research and development, engineering design, core equipment, and EPC, we strive to build a national level continuous flow fine chemical demonstration base and a chemist innovation and entrepreneurship platform, and embark on a new era of micro chemical industry that is “more efficient, safer, and environmentally friendly”.

Official Account

video

Recruitment

网页版权所有:豪迈集团股份有限公司 © 2023 Himile Group Co.,Ltd 鲁ICP备12027180号 鲁公网安备37078502370929号

Employee complaints:13864673866/13864673866@163.com|Email login|Human Resources:0536-2361016 / 13806360005